Green Industry

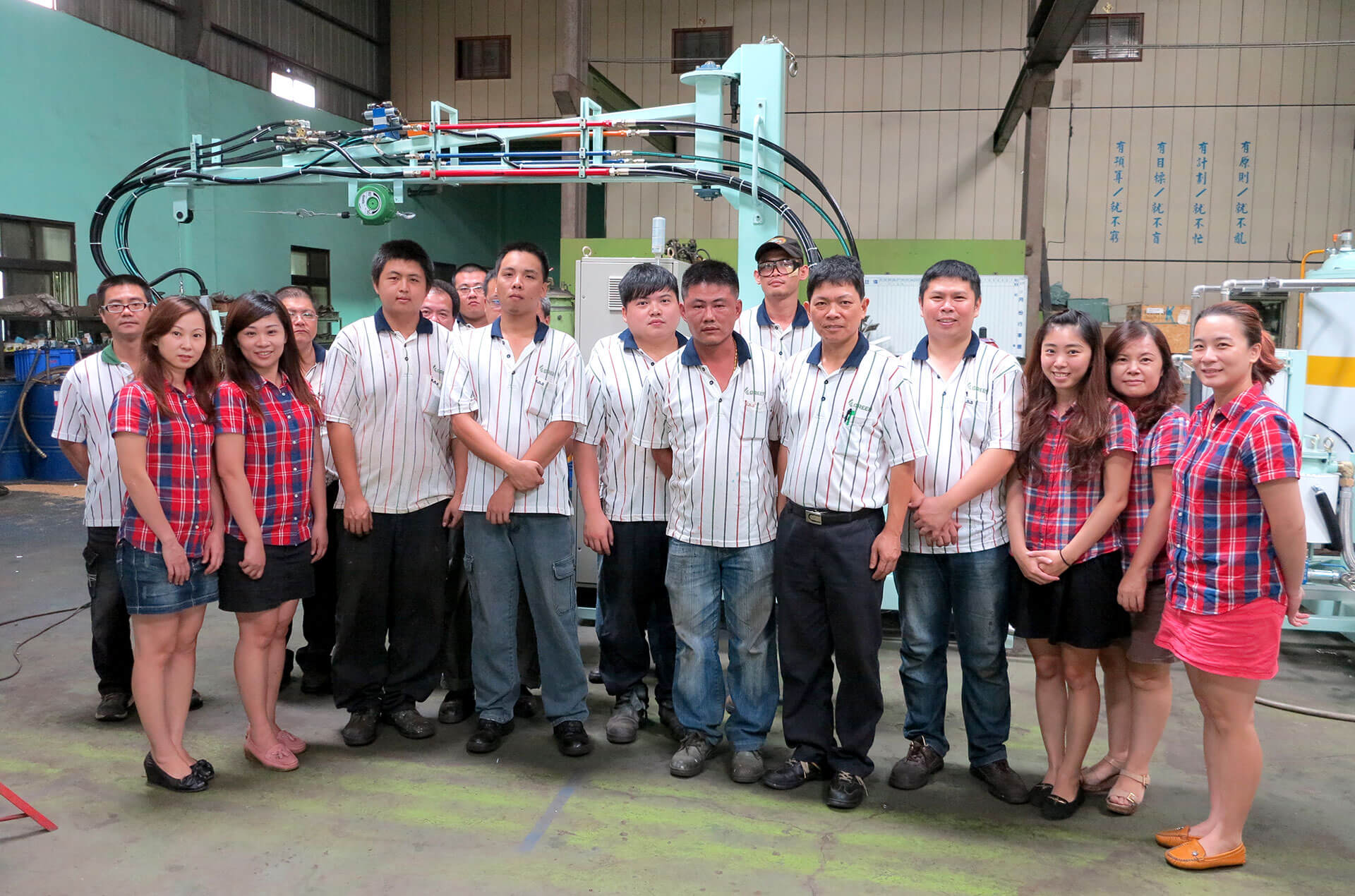

Taiwan Green Industrial Co., Ltd. was founded in Taichung City, Taiwan in 1981.

It is a professional manufacturer of polyurethane equipment integrating R&D, design, manufacturing, sales and service.

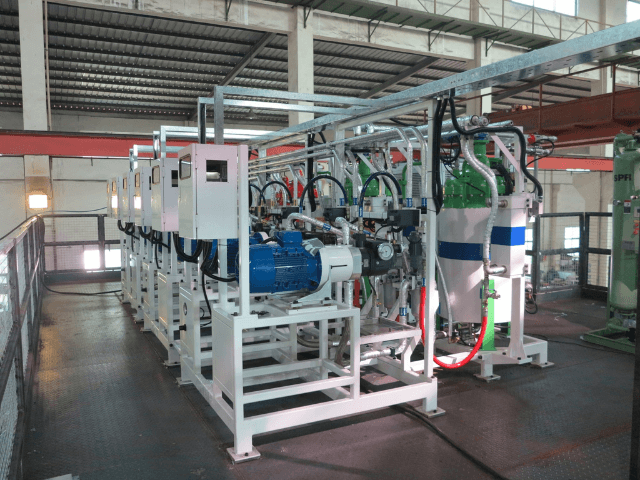

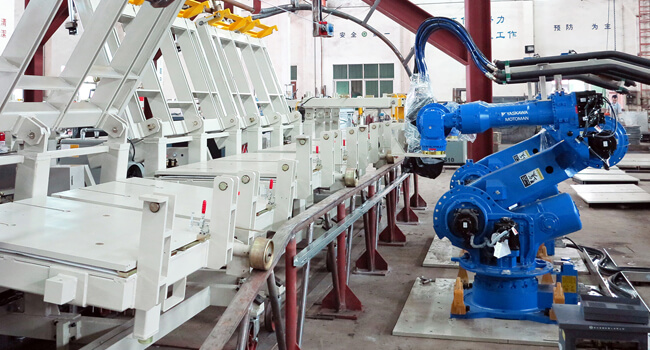

It has a history of more than 30 years so far. In 2001, Dongguan Green Machinery Equipment Factory was established in Dongguan, Guangdong, a famous manufacturing city.

Product Showcase

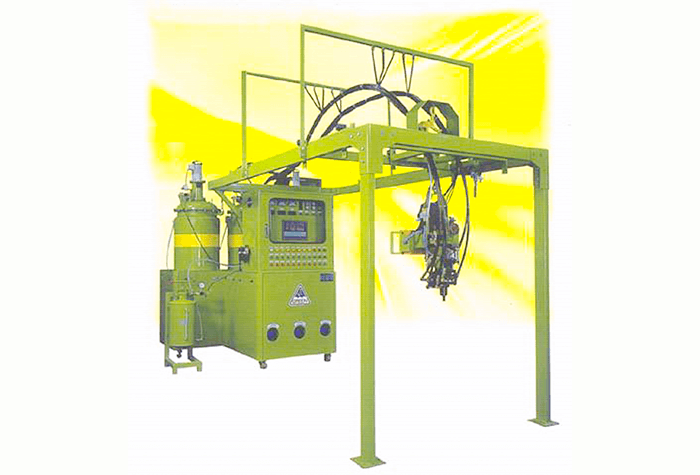

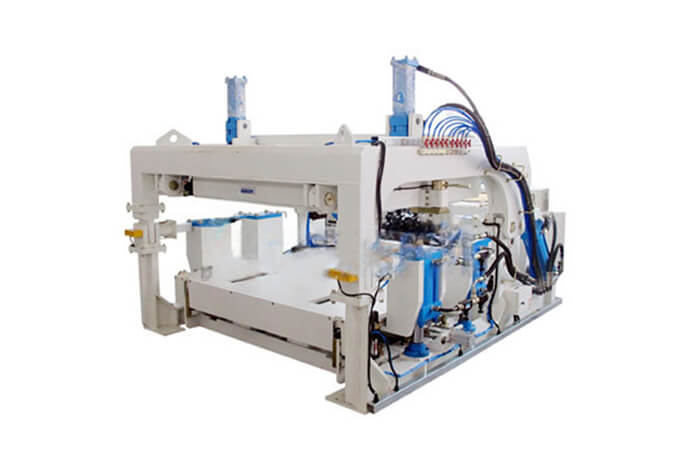

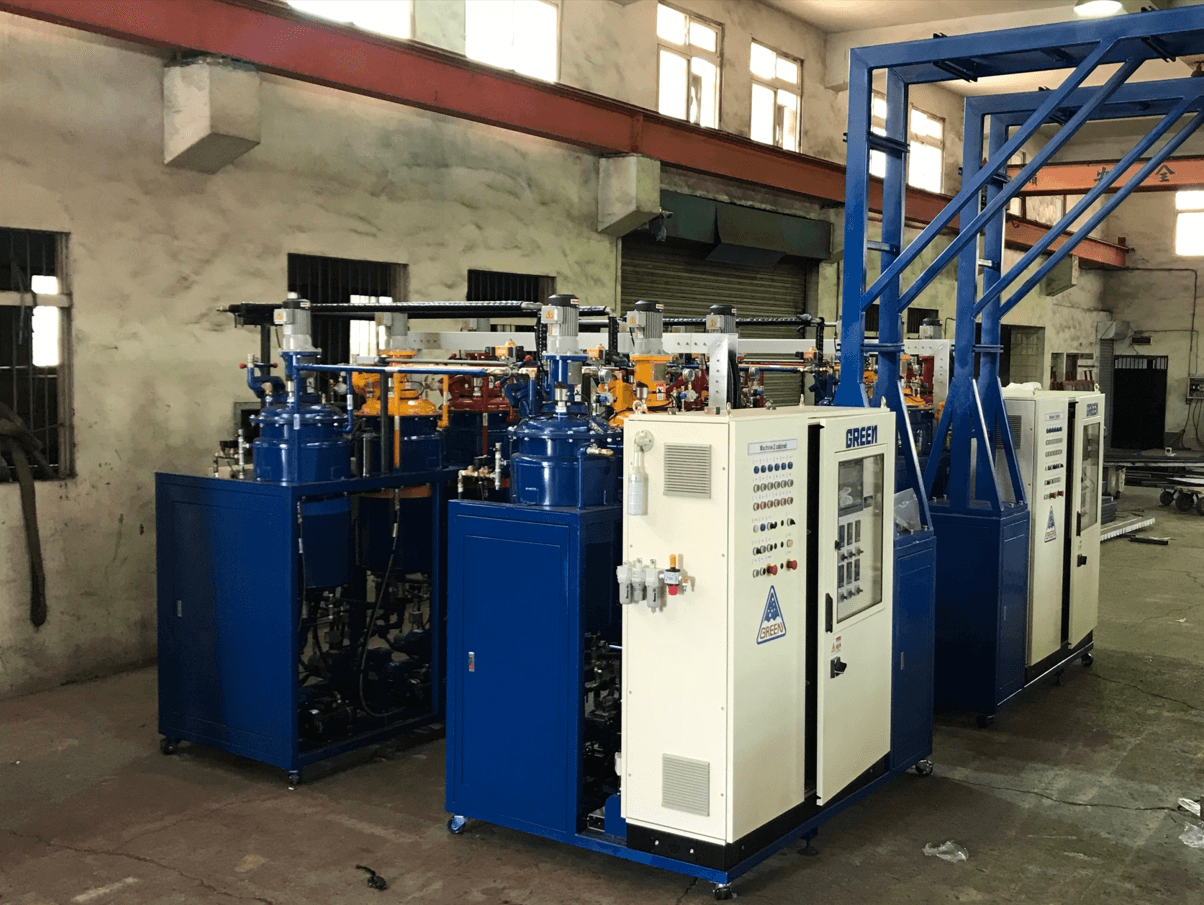

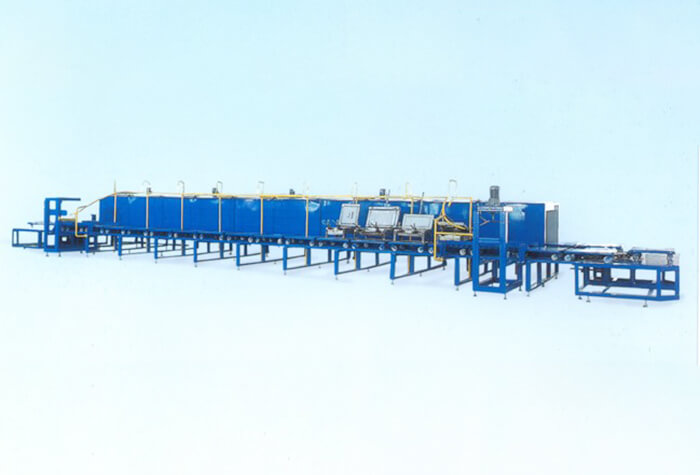

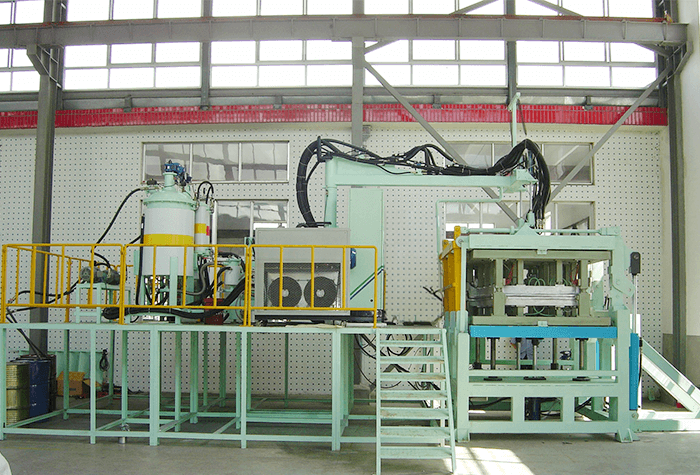

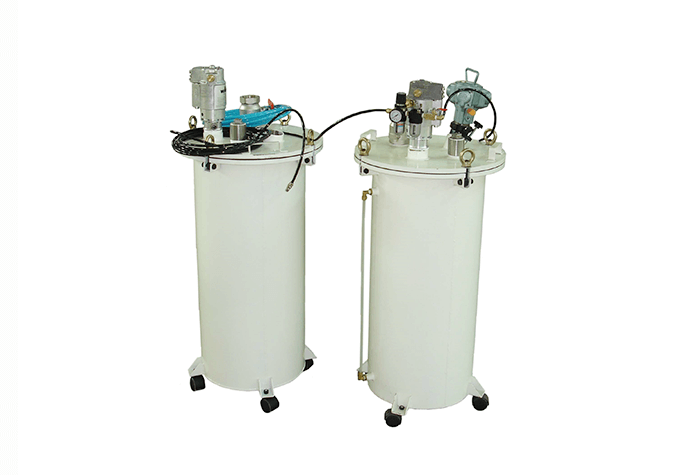

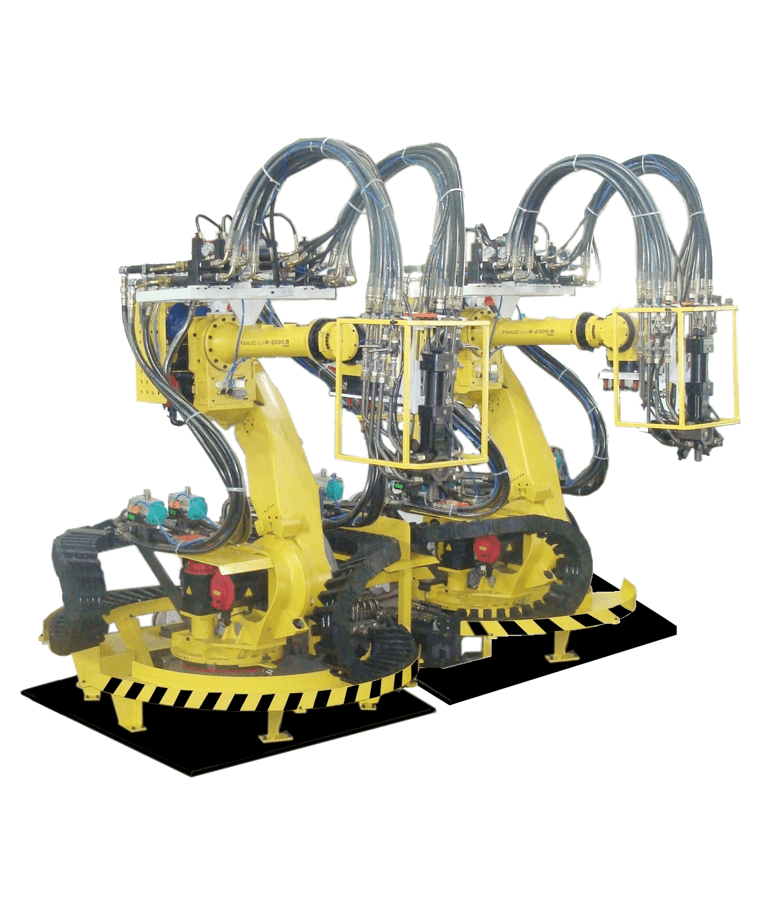

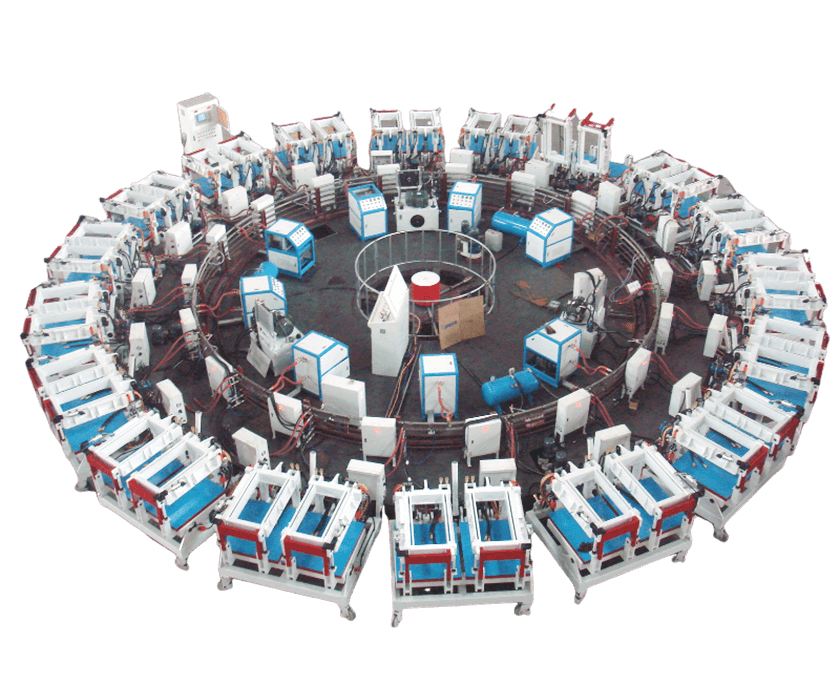

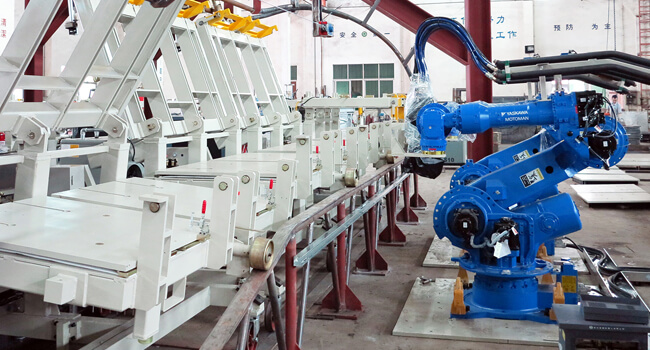

GREEN's main products: polyurethane (PU) high-pressure foaming machine, PU low-pressure foaming machine, CPU & Hybrid system, peripheral supporting equipment, etc. The entire plant is a turnkey project.

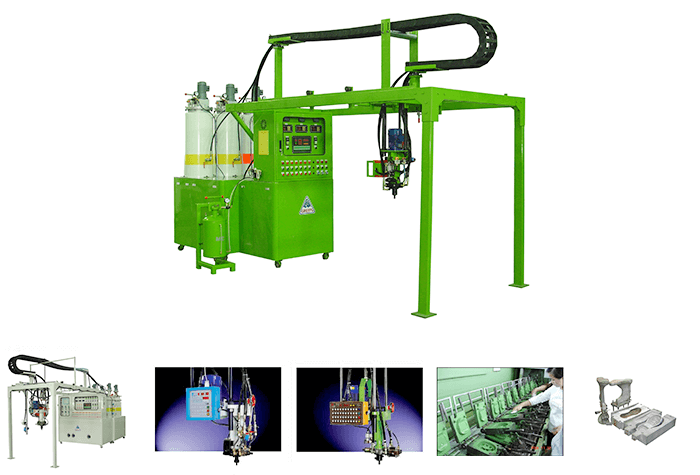

PU LP Pouring Machine

Key Features and Advantages of Low-Pressure PU Foam Injection Machines

- Gentle Mixing Process: Mechanical mixing at low pressure reduces stress on molds and components, ensuring the integrity of delicate parts.

- Operational Simplicity: User-friendly interfaces and straightforward maintenance procedures make these machines accessible to operators with varying skill levels.

- Cost-Effective Production: Lower equipment and maintenance costs, combined with reduced energy consumption, contribute to overall cost savings.

- Versatility: Capable of handling a wide range of PU formulations, including those with fillers or additives, to meet diverse production requirements.

- Customization: Easily adaptable to specific production needs, allowing for modifications in output rates, mixing ratios, and mold configurations.

Applications of Low-Pressure PU Foam Injection Machines

-

Furniture and Bedding

Widely used in the production of cushions, mattresses, armrests, and ergonomic seating components. These machines support custom mold designs and variable foam densities, making them suitable for both comfort-focused and orthopedic products. -

Automotive Industry

Applied in the manufacturing of vehicle interior components such as headrests, side bolsters, trunk liners, and insulation panels. Their ability to fill complex molds with minimal stress makes them ideal for parts with irregular shapes or dual-hardness foam designs. -

Construction and Insulation

Used for producing rigid foam insulation boards, sealant fillers, and lightweight architectural elements. The stable and uniform mixing process ensures long-term performance in temperature and moisture control, contributing to energy-efficient building designs. -

Consumer Goods

Effective for fabricating molded foam items like household sponges, novelty products, toy inserts, and customized packaging. Their precision enables consistent reproduction of intricate shapes, which is essential for branding and user experience. -

Medical Equipment and Care Products

Employed in the development of patient-support cushions, wheelchair pads, neck supports, and other healthcare foam components. The machines' fine control over material flow and formulation meets strict medical-grade standards for hygiene, pressure relief, and durability.

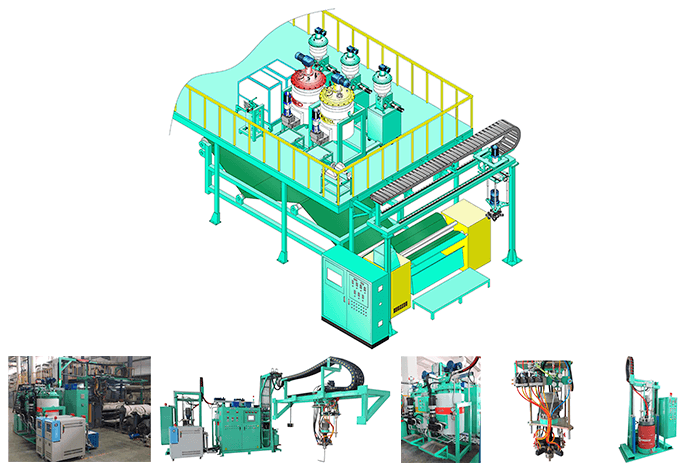

PU HP Pouring Machine

Key Features and Advantages of High-Pressure PU Foam Injection Machines

- Precision Mixing and Metering: Advanced metering systems guarantee accurate chemical ratios, resulting in uniform foam density and quality.

- Efficient Production: High-pressure systems enable rapid cycle times, increasing throughput and reducing production costs.

- Versatility: Suitable for a wide range of applications, from flexible to rigid foam products, accommodating various industry needs.

- Energy Efficiency: Optimized designs reduce energy consumption, contributing to sustainable manufacturing practices.

- User-Friendly Operation: Equipped with intuitive controls and automated features, these machines simplify operation and maintenance.

Applications of High-Pressure Polyurethane Foam Injection Machines

-

Automotive Industry

These machines are used to produce car seats, dashboards, armrests, and other interior components that require durable and comfortable foam materials. With high-speed injection and uniform mixing, they ensure consistent product quality over long production runs. -

Furniture Manufacturing

Ideal for manufacturing cushions, mattresses, and ergonomic seating products, high-pressure PU foam machines deliver uniform density and support layered foam applications. They are commonly used in both residential and commercial furniture production lines. -

Construction and Insulation

In the building sector, these machines are used to fabricate insulation panels, wall boards, and other components that demand high thermal resistance. The precision of high-pressure injection helps improve material bonding and structural strength. -

Appliance Industry

For home and industrial appliances, PU foam provides insulation in refrigerators, freezers, and water heaters. Injection accuracy ensures better thermal efficiency and helps meet strict energy-saving regulations. -

Protective Packaging

These machines are also used to create protective foam packaging for sensitive items such as electronics, instruments, or precision tools, where shock absorption and shape adaptability are key.

Quality system certification. Won multiple national patents

Our Service

-

Equipment consultation and applicationExplanations and Consultations

Customer Needs Analysis

Training on Equipment Operation

Application Scenario Design

Customized Solutions -

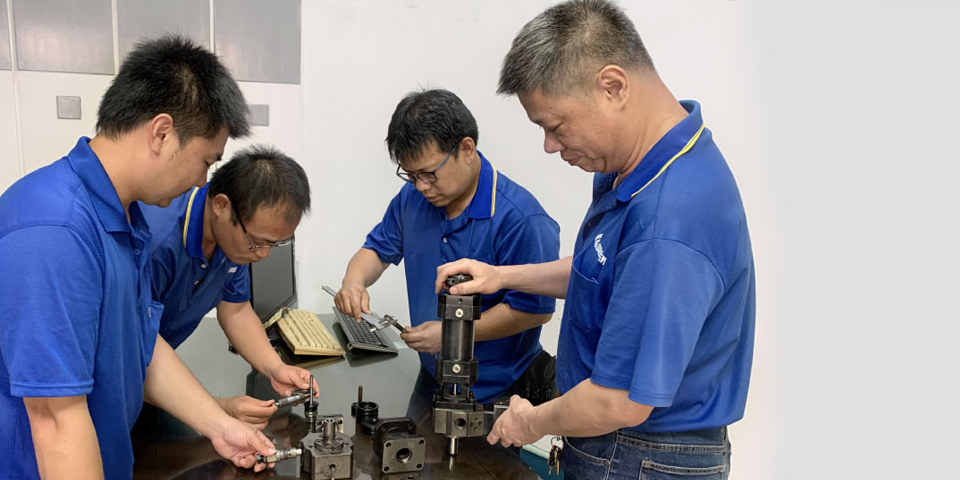

After ServiceProfessional & Efficient technical team

Special person to handle machine failure

Original spare parts and wear & teat parts

Pursue excellence and perfection

quick response & service system -

Technical SupportRemote Internet Monitoring

Whole Plant Layout

Consultative

Technical Communication

Together develop new product and mold with customer -

Education TrainingOnsite Training

Machine Operation and Maintenance

Professional Equipments in Lab

Special training course available on customer's request

American Johnson Group, American Lear Group, French Faurecia, FEHRER (Germany Ferrar), FUTURIS (American Fuzhou), AUTONEUM French factory

Japanese users

Japan TQ1, Japan INOAC Inoue Group, Japan TOYO TIRES Group, Japan Futaba Group, TAKAYA Chemicals, Bridgestone BRlDGEST0NE

Taiwan users

Yulon Group, Sanyo Home Appliances, Baocheng Group, Futai Group, Xingang Group, Qingyu Group, Hongfu Group, Longdian Group, Wanbang Group, Quanxing Group, Hecheng Sanitary Ware, Nanya Group

China Users

China South Locomotive & Rolling Stock Corporation, JCI Shenyang Jinbei, BYD, Yutong Bus, King Long Bus... and other professional equipment suppliers

Applications

GREEN equipment application range: rigid foam, soft foam, self-skinning foam, insulation materials, elastomers, footwear materials, etc.

GREEN equipment service areas: automotive and motorcycle interiors, household appliances refrigeration, shoemaking, faux wood furniture, decorative building materials, leather coating, toys, electronics industry, etc.

Application scope of GREEN equipment: rigid foam, soft foam, self-made leather, thermal insulation materials, elastomers, shoe materials, etc.

GREEN equipment application scope: rigid foam, soft foam, self-made leather, thermal insulation materials, elastomers, shoe materials, etc.

GREEN equipment service areas: automobile and motorcycle interior parts, home appliance refrigeration, shoemaking, imitation wood furniture, decorative building materials, leather coating, toys, electronic industry, etc.

News

The latest news and related developments about Green Industry