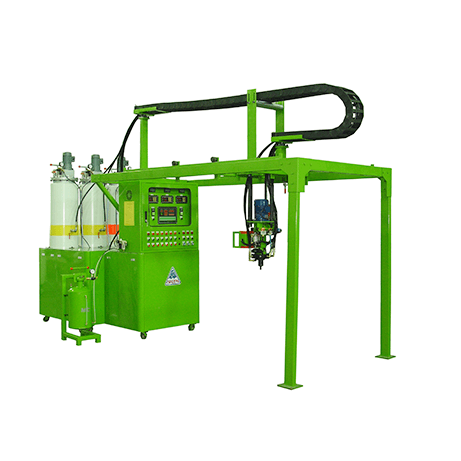

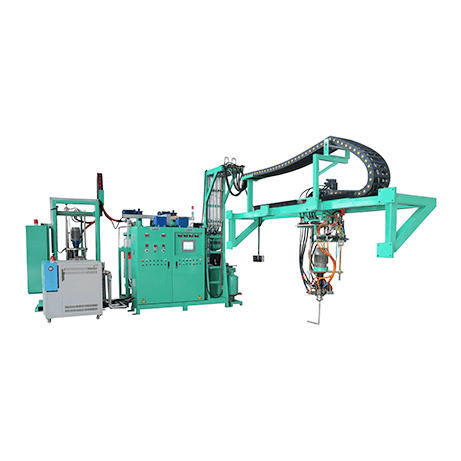

PU LP Pouring Machine

Low-pressure polyurethane (PU) foam injection machines are designed for applications requiring precise control and gentle processing conditions. Unlike high-pressure systems that utilize dynamic mixing under force, low-pressure machines employ mechanical mixing at atmospheric pressure, making them ideal for producing intricate or delicate components. These machines are particularly suited for small to medium-scale production where flexibility, ease of operation, and cost-effectiveness are paramount.

Key Features and Advantages of Low-Pressure PU Foam Injection Machines

- Gentle Mixing Process: Mechanical mixing at low pressure reduces stress on molds and components, ensuring the integrity of delicate parts.

- Operational Simplicity: User-friendly interfaces and straightforward maintenance procedures make these machines accessible to operators with varying skill levels.

- Cost-Effective Production: Lower equipment and maintenance costs, combined with reduced energy consumption, contribute to overall cost savings.

- Versatility: Capable of handling a wide range of PU formulations, including those with fillers or additives, to meet diverse production requirements.

- Customization: Easily adaptable to specific production needs, allowing for modifications in output rates, mixing ratios, and mold configurations.

Applications of Low-Pressure PU Foam Injection Machines

-

Furniture and Bedding

Widely used in the production of cushions, mattresses, armrests, and ergonomic seating components. These machines support custom mold designs and variable foam densities, making them suitable for both comfort-focused and orthopedic products. -

Automotive Industry

Applied in the manufacturing of vehicle interior components such as headrests, side bolsters, trunk liners, and insulation panels. Their ability to fill complex molds with minimal stress makes them ideal for parts with irregular shapes or dual-hardness foam designs. -

Construction and Insulation

Used for producing rigid foam insulation boards, sealant fillers, and lightweight architectural elements. The stable and uniform mixing process ensures long-term performance in temperature and moisture control, contributing to energy-efficient building designs. -

Consumer Goods

Effective for fabricating molded foam items like household sponges, novelty products, toy inserts, and customized packaging. Their precision enables consistent reproduction of intricate shapes, which is essential for branding and user experience. -

Medical Equipment and Care Products

Employed in the development of patient-support cushions, wheelchair pads, neck supports, and other healthcare foam components. The machines' fine control over material flow and formulation meets strict medical-grade standards for hygiene, pressure relief, and durability.