Automotive Interior Parts

Why Polyurethane Foam Is Ideal for Car Seats and Interior Parts

Polyurethane (PU) foam has become the industry standard for automotive seating due to its unique combination of comfort, resilience, and design flexibility. Whether used in seat cushions, backrests, or headrests, PU foam provides excellent cushioning, long-term durability, and lightweight structure—all of which contribute to enhanced passenger comfort and fuel efficiency. Its moldability allows carmakers to create ergonomic and visually appealing interiors tailored to diverse consumer needs.

Types of Polyurethane Foam Used in Automotive Seating

Automotive seats utilize various types of PU foam depending on performance and comfort requirements:

- High Resilience (HR) Foam – Delivers bounce and long-term support.

- Molded Flexible Foam – Used for precise seat shaping and comfort zones.

- Integral Skin Foam – Combines surface durability with soft cushioning, ideal for armrests and headrests.

- Multi-Density Foam Structures – Layered foam systems that optimize comfort and stability in different seating zones.

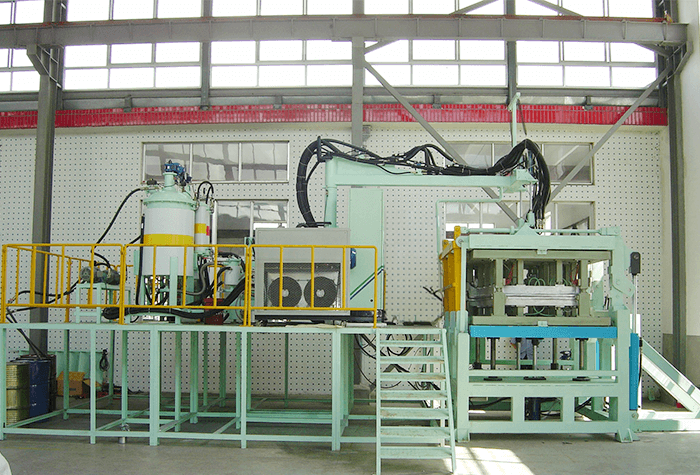

Applications and Production Integration with PU Injection Machines

Polyurethane foam is used across multiple interior components, including:

- Seat cushions and backrests

- Headrests and side bolsters

- Armrests and center consoles

- Door panels and trim padding

- NVH (Noise, Vibration, Harshness) insulation parts

Green Industrial’s PU foam injection systems—such as rotary seat production lines and low/high-pressure pouring machines—are designed to meet the demands of mass automotive production. We offer customizable solutions for complex mold shapes, fast cycle times, and multi-material integration, helping OEMs and Tier 1 suppliers improve efficiency and quality.